When Your Product Needs Micron-Level Accuracy

Our turnkey solutions combine proven test & measurement, control systems, machine vision, gluing/welding and robotics.

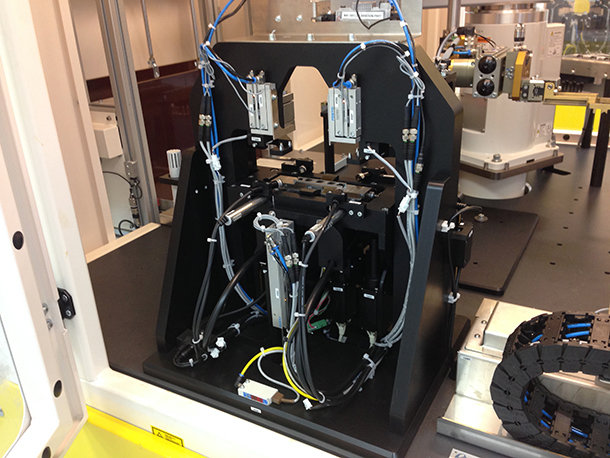

VISION, SENSORS & ALIGNMENT

Our expertise in vision inspection, mechatronics and control systems comes together in extremely precise alignment operations based on sensor feedback.

HANDLING & GLUING/WELDING

We use the latest absolute-positioning technologies to support automated gluing or ultrasonic welding operations, followed by UV or oven curing.

ASSEMBLY & PRODUCTION

Our turnkey systems can ensure both high throughput and perfectly accurate assembly. Depending on your needs, they can be semi- or fully automated.

Due to the continuing trend of product miniaturization and increased complexity, accurate gluing, welding, laser and assembly solutions are key in next-generation devices. As a result, the clear distinction between assembly and testing starts to blur. In smartphones, for example, testing and soldering the battery is one step in the production process. Hence, a combination of ultra-precise dosing, fixation, positioning and real-time feedback is essential to ensure best results and maximum reliability.

If your product requires ultra-precise handling, positioning and component joining/assembly, an Averna turnkey solution will ensure maximum reliability, efficiency and output. Our multidisciplinary capabilities in sensors, machine vision, control systems, handling/robotics, gluing and quality inspection ensure we can solve even the most challenging product assembly and production tasks.

- Ultra-precise handling, positioning and assembly at micron level

- Automatic gluing stations for all types of glue with UV curing or ovens

- Ultrasonic welding equipment available

- Vision-guided mechatronics for micron-accurate absolute positioning

- Full integration of vision inspection, quality, gluing, and assembly modules

- High throughput and semi- or full automation

(우)07299 서울특별시 영등포구 경인로 775 (문래동 3가, 에이스하이테크시티 3동 2층)