We've Got Your Systems Under Control

Tap our leading design, implementation, industry and support experience,

backed by our CSIA registration and extensive UL listings capabilities.

Are you looking for a partner with extensive industrial control-system expertise? We have delivered numerous turnkey solutions for oil & gas, power, medical and pharmaceutical customers, including for hazardous locations.

Want a fully integrated control system for design verification purposes? We are experts in turnkey real-time systems that can put your products through their paces for thousands of hours while providing rich performance data.

Need a completely automated solution to drive exceptional results in a production environment? Our systems engineers work closely with our vision inspection and product-handling experts to ensure optimum quality, throughput and reliability.

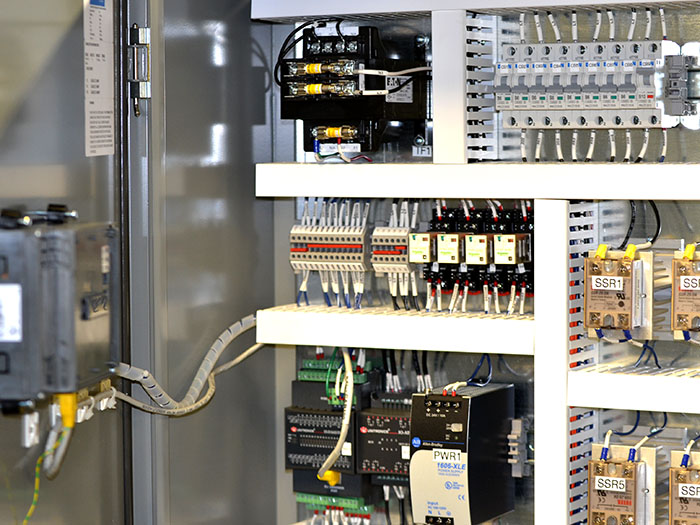

Averna designs control systems and control panels to operate with maximum precision and reliability in some very demanding and hazardous environments. For example, we are experts in:

- Industrial controls, process controls, and pneumatics

- PLC and discrete-based control of pumps, motors, heaters, blowers, etc.

- Industrial process monitoring and logging

- PLC programming, HMI and Web-enabled systems

- SCADA (Supervisory Control And Data Acquisition)

- UL Listing: UL 508A: Industrial Control Panels

- UL Listing: UL 698A: Industrial Control Panels Relating to Hazardous (Classified) Locations

- UL Listing : Control panels that reside within a hazardous / classified location based on component regulations that may include UL 1203, NFPA 496, UL 1604, or UL 60079, depending on the specific application

Design verification for industrial products, vehicle parts and aerospace components is essential to safety, long product life and brand protection. That's why numerous customers count on our know-how for designing and implementing control systems and equipment that thoroughly test and verify their new products. You get optimum results from our expertise in:

- Electro-mechanical test stands for closed-loop, lifecycle testing

- Environmental, vibration and noise testing

- Condition monitoring for predictive maintenance

- 3D modelling (SolidWorks) and data acquisition (DAQ)

- Hardware in the Loop (HIL) and embedded systems

- LabVIEW RT, LabVIEW FPGA, and CompactRIO

Averna is renowned for its leading edge, automated control and quality assurance systems for production testing and verification of vehicle drive-trains, dashboard assemblies, medical devices, food, packaging and many other products. Our integrated solutions for these applications emphasize high speed and zero defects, and can include some or all of these capabilities and components:

- Vision inspection and machine vision systems

- Robotics, pneumatics and motion-enabled product-handling

- Automation, condition monitoring and data acquisition (DAQ)

- System identification, calibration and simulation

- Custom control algorithms, analysis and visualization

- Integration with sensors, actuators and custom or NI hardware (CompactRIO, Single-Board RIO, etc.)

Averna provided design, sourcing, assembly and verification services on hundreds of Asset Monitoring Nodes for use in power generation facilities. When installed throughout a power plant, these NI CompactRIO-based nodes form a cost-effective, condition monitoring network that collects and analyzes performance from all of the equipment critical to power generation.

Averna designed and implemented a LabVIEW-based, real-time system to monitor 100 input channels of temperature, flow and pressure associated with the engine under test and the environment with the test chamber. An additional 40 output channels were integrated within the existing control hardware, software and engine's main computer to supervise the control of the test system.

Averna's high-speed, comprehensive system includes 2D matrix cameras that check for roundness, 360-degree cameras that check for dimensions and automated processing that checks for contamination to verify that all the client's products are uniform and ready for shipping, ensuring both brand protection and fast time to market.

(우)07299 서울특별시 영등포구 경인로 775 (문래동 3가, 에이스하이테크시티 3동 2층)